How to Source Injection Molding Services from China

The important meeting has recently finished, your new product is a go, the schedule is tight, and funding is, to put it mildly, limited. Then a voice—perhaps your manager or the CFO—drops the line that gives every project manager a shock: “We should look at sourcing this from China.”

Of course, you acknowledge. On paper, it’s logical. Savings can be substantial. However, your brain is racing with concerns. You know the rumors, don’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It feels like walking a thin line between big savings and total project failure.

Here’s the thing, though. Sourcing China injection molding doesn’t have to be a gamble. It’s no different from any structured project. And its outcome hinges on the approach you take. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Ignore the nightmare anecdotes. Let’s go through a step-by-step guide to succeed.

Step One: Do Your Homework

Before you even whisper the word “supplier” or open a browser tab to Alibaba, you need to get your own house in order. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. You cannot expect overseas partners to interpret your unspoken requirements. Sending a vague request is like asking a builder to quote you for “a house.” You’ll get wildly varied quotes that are useless.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. It’s the cornerstone of your entire effort.

So, what goes in it?

Begin with 3D CAD models. These are non-negotiable. Stick to universal formats like STEP or IGS to avoid any compatibility headaches. This is the authoritative CAD geometry.

However, 3D alone won’t cut it. You also need detailed 2D drawings. Here you specify what 3D can’t show. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Next up, material. Avoid generic terms like “Plastic.” Don’t even just say “ABS.” Be explicit. If you need SABIC Cycolac MG38 in black, say exactly that. Why? Because there are thousands of plastic variations. Naming the precise grade locks in the mechanical, thermal, and aesthetic properties you need with what is plastic mold.

Your supplier might propose substitutes, but you must set the baseline.

Don’t forget the commercial info. State your EAU. A supplier needs to know if they’re quoting a tool that will make 1,000 parts in its lifetime or 1,000,000 parts a year. Tool style, cavity count, and unit cost are volume-driven.

The Great Supplier Hunt

Now that your RFQ is pristine. who will you target? The web is vast but overwhelming. Finding suppliers is simple; finding quality ones is tough.

You’ll probably kick off on Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. Use them to build a shortlist, not the final list. Aim for a preliminary list of 10–15 potential partners.

But don’t stop there. Consider using a sourcing agent. Yes, they take a cut. But a reputable agent brings pre-screened factories. They handle local liaison and oversight. For a first-time project, this can be an invaluable safety net. It’s schedule protection.

Also consider trade fairs. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. Meeting onsite is unbeatable. Inspect prototypes, interview engineers, and sense their capabilities. And don’t forget the oldest trick in the book: referrals. Ask other project managers in your network. A solid referral can be more valuable than any ad.

Shortlisting Serious Suppliers

After firing off that RFQ to a broad pool, the quotes will start trickling in. You’ll see ridiculously low offers and steep quotes. Now, sift through and shortlist 2–3 reliable candidates.

What’s the method? It blends technical checks with intuition.

Step one: audit communication. Do they respond quickly and clearly? Do they communicate effectively in English? But here’s the real test: Are they asking you intelligent questions? Top vendors will critique and inquire. Example: “Should we add draft here for better ejection?” or “Your tolerance may require extended CMM time—okay?” That’s a huge positive sign. You know they know their stuff. A supplier who just says “No problem” to everything is a walking red flag.

Next, dig into their technical capabilities. Get their tooling inventory. Seek samples or case studies of comparable projects. If you’re making a large, complex housing, you don’t want a shop that specializes in tiny gears.

Then comes the audit. You can’t skip this. You would never hire a critical employee without an interview, so why would you send tens of thousands of dollars for a tool to a company you’ve never truly vetted? You can travel or outsource a local inspector. They’ll send a local inspector to the factory for a day. They confirm legitimacy, audit ISO 9001, inspect equipment condition, and gauge the facility. It’s a tiny cost for huge peace of mind.

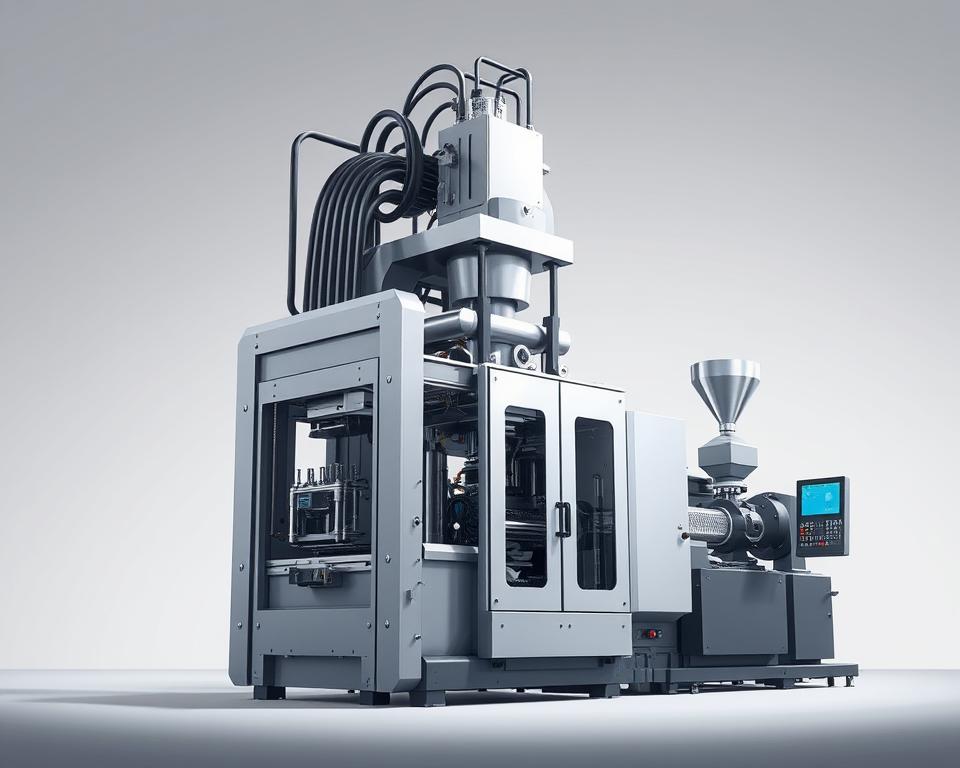

Converting Digital Designs into Molded Parts

After picking your vendor, you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the process kicks off.

Initially, expect a DFM report. Design for Manufacturability (DFM) is essential. This is your supplier’s formal feedback on your part design. It will highlight potential issues like areas with thick walls that could sink, sharp corners that could cause stress, or surfaces without enough draft angle for clean ejection from the mold. Comprehensive DFM equals a top-tier supplier. It’s a collaboration. You work with their engineers to refine the design for optimal production.

Once the DFM is approved, they’ll start cutting steel to make your injection mold tool. In a few weeks, you’ll see “T1 samples are on the way.” These represent the first trial parts. It’s your test of success.

T1 parts usually require adjustments. This is normal! You’ll find minor defects, off-spec dimensions, or finish issues. You supply feedback, they tweak the tool, and T2 plastic mold samples follow. It could require several iterations. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

Finally, a flawless part arrives. It meets every dimension, the finish is flawless, and it functions exactly as intended. This becomes the “golden sample.” You ratify it, and it becomes the quality yardstick for production.

Completing the Sourcing Journey

Landing the golden sample is huge, yet the project continues. Next up: mass manufacturing. How can you keep part #10,000 matching your golden sample?

You need a clear Quality Control plan. Often, you hire a pre-shipment inspection service. Use a third-party inspector again. They’ll randomly select parts, compare them to specs and golden sample, and deliver a detailed report. They provide a photo-filled inspection report. Only after you approve this report do you authorize the shipment and send the final payment. This audit shields you from mass defects.

Lastly, plan logistics. Clarify your Incoterms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or is it EXW (Ex Works), where you are responsible for picking it up from their factory door? Your Incoterm selection drives landed expenses.

Overseas sourcing is a marathon. It relies on partnership-building. View them as allies, not vendors. Open dialogue, trust, and rigorous procedure deliver results. Certainly, it’s complex. But with this framework, it’s one you can absolutely nail, delivering the cost savings everyone wants without sacrificing your sanity—or the quality of your product. You’re set to succeed.